Prepare Soldering Station

This is the Tuna Flapping build (1 motors 1 servo) that is compatible with the Jellyfish Propeller build (1 motor) and the Tuna Propeller build (2 motors 1 servo).

If you have already made one of the blimps listed prior please skip to the motor assembly, if you have made a blimp prior and it is not listed above please skip to step 8. If not please continue to follow the guide below. For experienced makers you can skip to the wiring diagram to make the correct system with motors and servos.

- Turn on a fan or open windows if possible

- Wet the sponge that goes with the soldering iron – it is to remove excess solder from the iron

- Set soldering station temperature to 320 degrees Celsius

- Set-up stand so that the soldering iron can rest on it

Attaching Pins to the “Feather Huzzah” Referred to as “The Board”

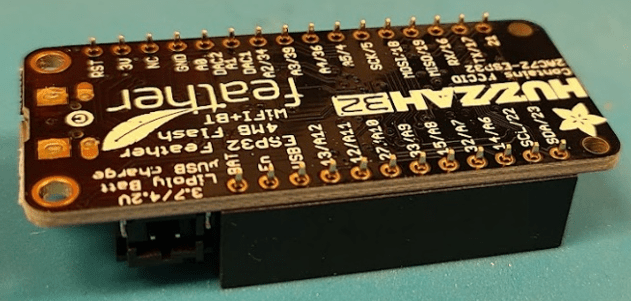

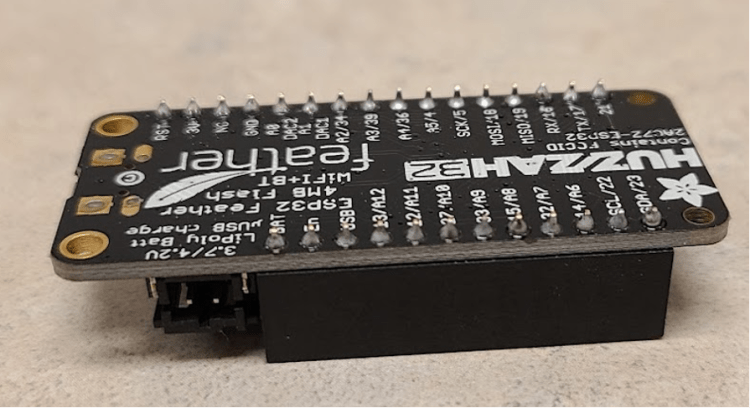

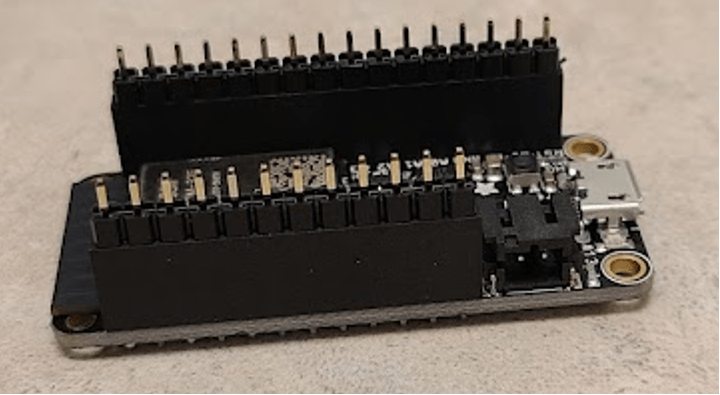

- Retrieve “Feather Huzzah” and “Feather header kit” from the Kit

- Insert female Header Pins into Feather Board and rest the board on them – everything should sit flat and square when it is positioned as below. If everything is square, you are ready to solder each of the pins to the board.

- To solder the pins to the board one at a time:

- Touch the soldering iron to the header board pins and pin hole at the same time.

- Note: Do not breath the fumes.

- Touch the solder wire to the pin and the board.

- Remove soldering iron and solder wire once the melted material looks like a cone around the pins

- If there is excess material on tip of soldering iron, use the wet sponge to clean the tip before starting on the next pin and working your way down both sides of the board until all pins have been soldered.

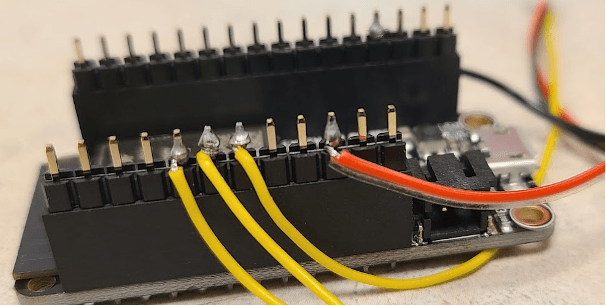

- Flip the board over and insert male Header Pins (longer side of the pins) into the top of the female Header Pins. If you have already made a previous system please take out the male Header Pins and replace them with a fresh set of male Header Pins to start making your new system.

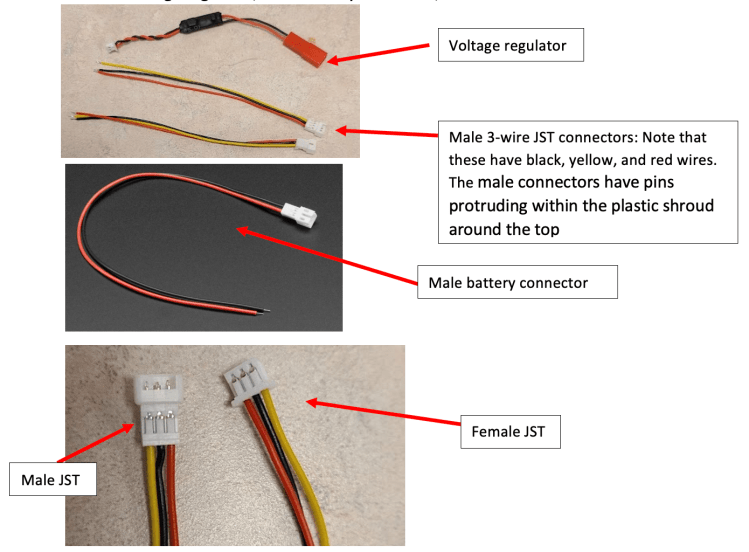

Preparing the Voltage Regulator Assembly

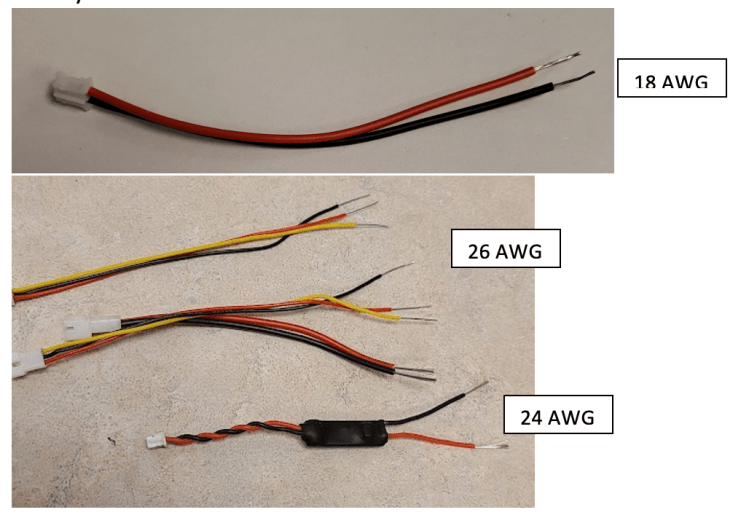

- Retrieve Voltage Regulator, male battery connector, and 2 male JST Connectors

- Use wire strippers (you can cut at the part that there are no dents for stripping off the plastic covering) to cut off red end of Voltage Regulator

- Use wire stripper (the dent marked for appropriate AWG) to remove about 1 centimeter of plastic from the free ends of the voltage regulator, JST wires, and the battery connector

- Twist ends of exposed wires to prevent fraying

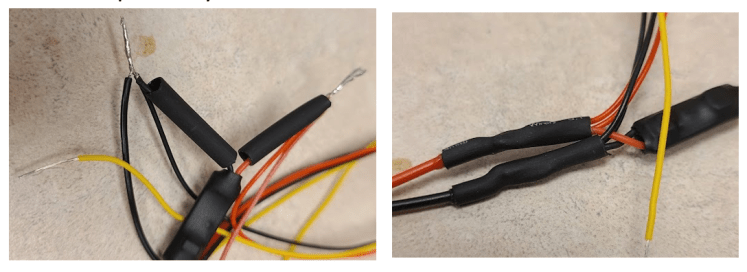

- Twist all 4 black wires together, and all 4 red wires together and use the yellow wire holder to hold them in place and then coat the wires with solder

- Bend wires to straighten and wrap black electrical tape around the exposed part of the wire. Tape red and black separately.

- Cut about 8 centimeters of rainbow-colored wire stack – note that there is a paper ruler in the kit if you need to measure.

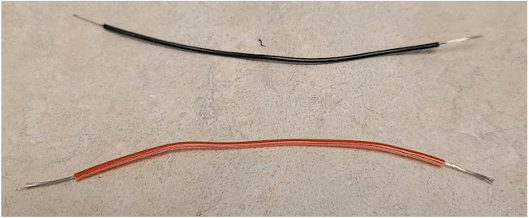

- Remove a red and a black wire from the stack (note that they are not on the ends) and strip about 1 cm of material off each side of both wires

- Retrieve another male JST connector and strip off 1 cm of material on all wires

- Cut the white head off the twisted black and red wires on the voltage regulator

- Twist together the 3 black wires (piece of wire, voltage regulator, and JST) and coat with solder then repeat for the 3 red wires unbending and covering each junction with electrical tape when you are finished.

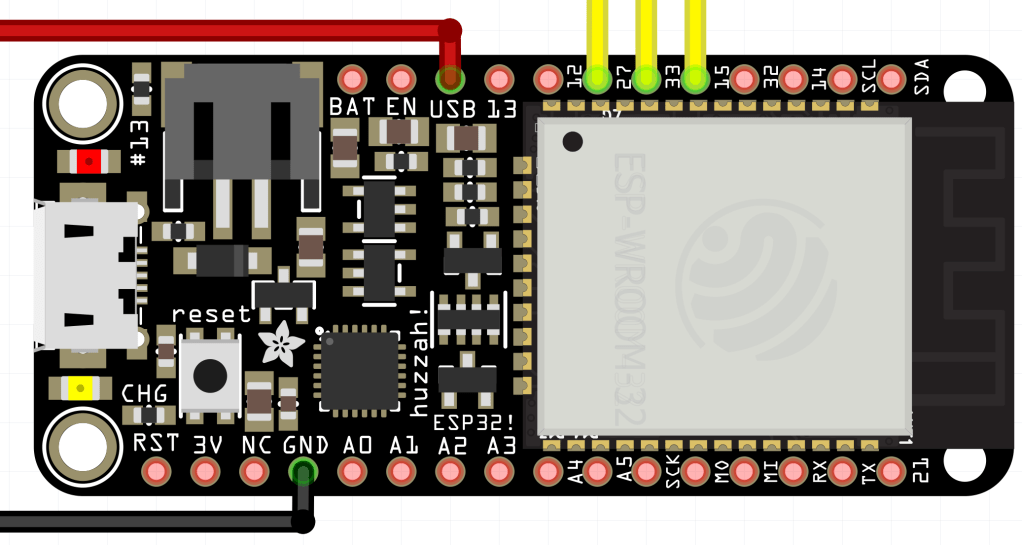

Wiring the “Feather Huzzah”

- Use the above diagram to identify which JST Connectors is for the tail servos (should be the one connected on its own to the Voltage Regulator) while the other two are to connect to the motors.

- Now use the diagram to identify which pin each of the wires connects to.

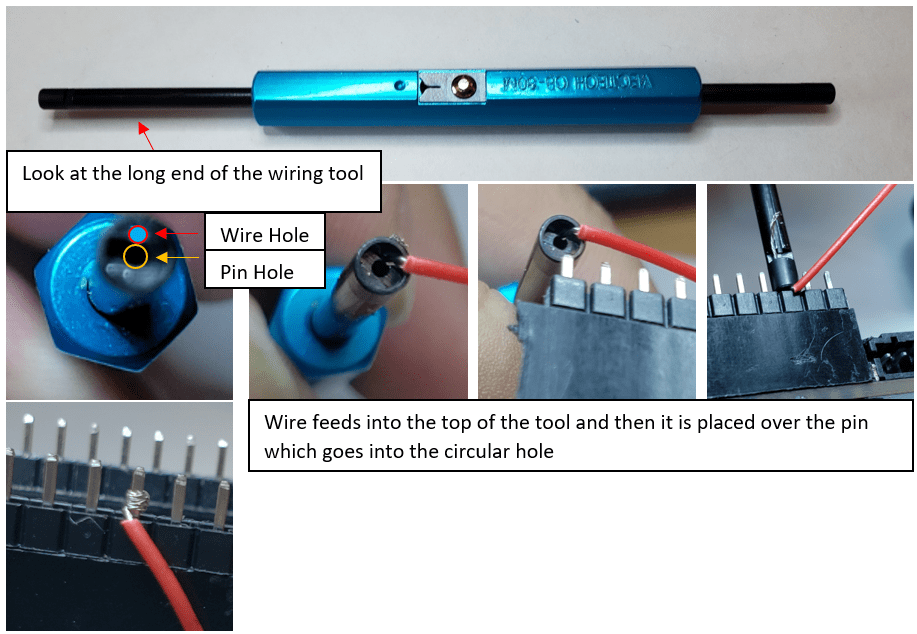

- Select one of the wires to start. Use the wire wrapping tool to twist the wire around the appropriate pin – insert the wire into the semi-circular hole at the top of the tool as far as it will go, bend the wire at a 90° angle so that it will stay inside the tool while the center hole is placed over the pin. Turn the tool so that the wire wraps around the pin. Repeat the wire wrapping for all of the wires in the diagram.

- Solder twisted wires on to the board being careful to not put on too much solder – the wires cannot touch other pins.

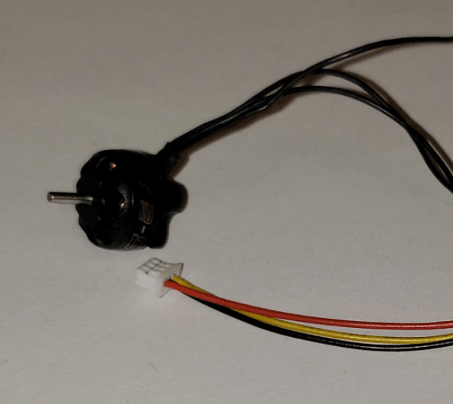

Preparing the Motors

- The ellipsoidal tuna uses 1 motors, so plug one Electronic Speed Controller (ESC) into the the male JST Connectors that are soldered to your Feather Board at pins 33 or 15.

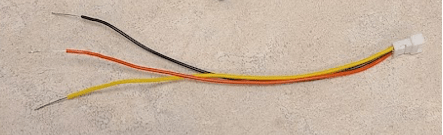

- Remove a servo from your kit, and cut off the black header attached to the servo (see picture below). Then attach a female JST connector to the servo connecting the wires Red to Red, White to Yellow, and Black to Black. As in the previous steps, strip 1 cm of plastic off the ends of the wires, twist wires together, apply solder, then cover with electrical tape.

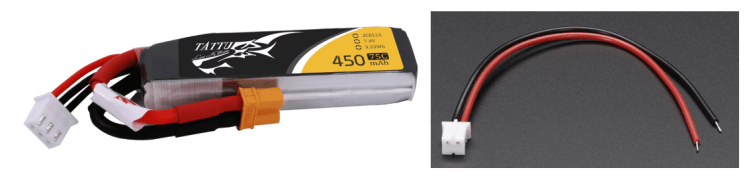

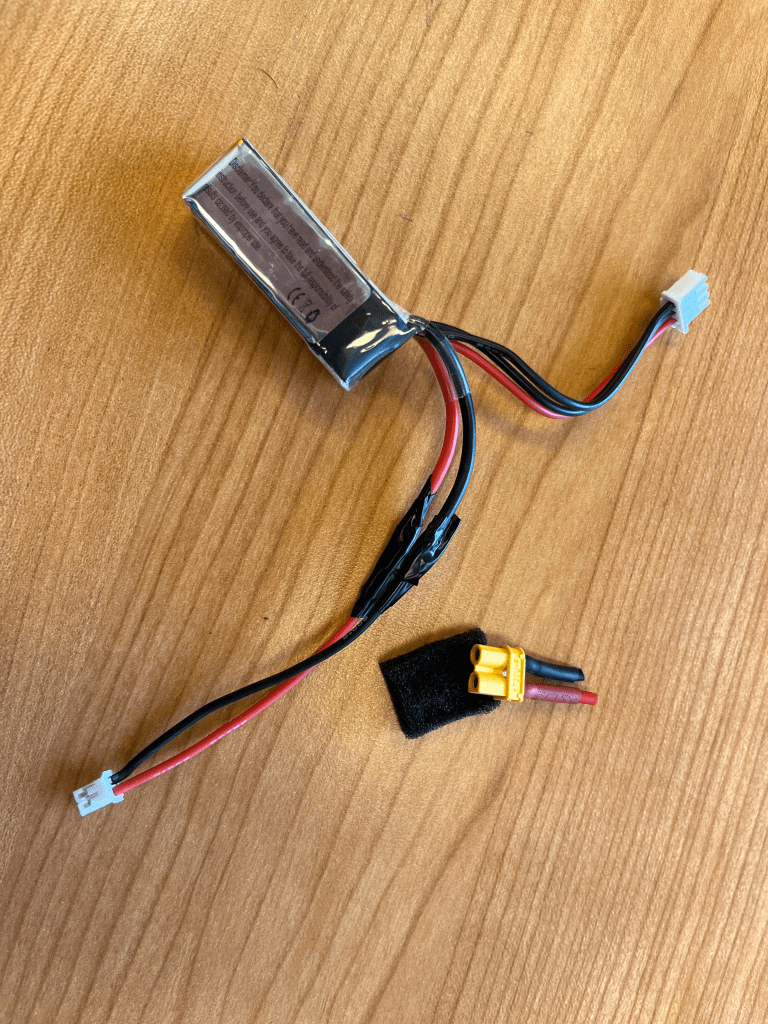

Battery Assembly

- Gather Battery Supplies – the battery and 2 pin female JST are needed. Note the white header with 3 wires connected to the battery is used for charging the battery.

- ONLY cut the red cable connected to the yellow header then solder the red wire of the 2-pin female JST to it and apply electrical tape. Cutting both the red and black wires at the same time could inadvertently short the battery.

- Cut the black cable connected to the yellow header then solder the black wire of the 2-pin female JST to it and apply electrical tape.

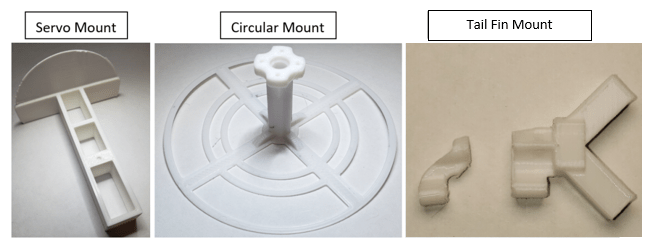

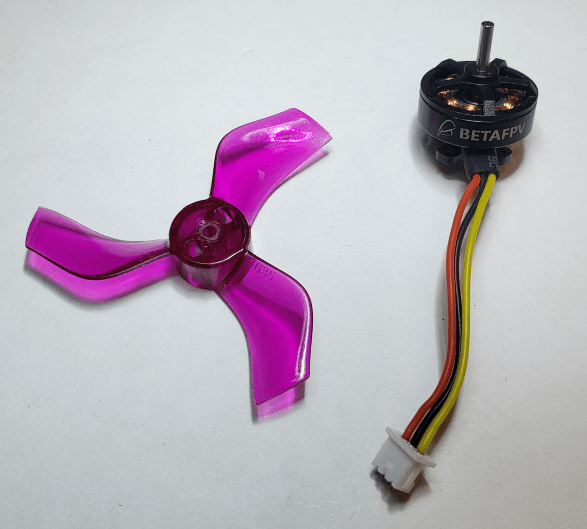

Motor Assembly

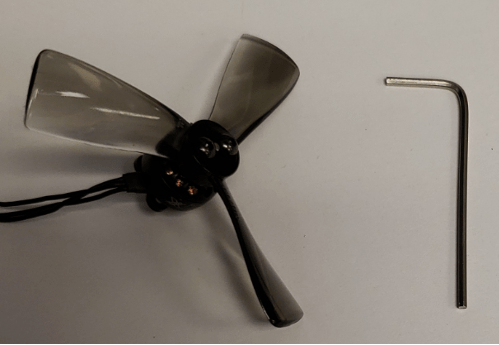

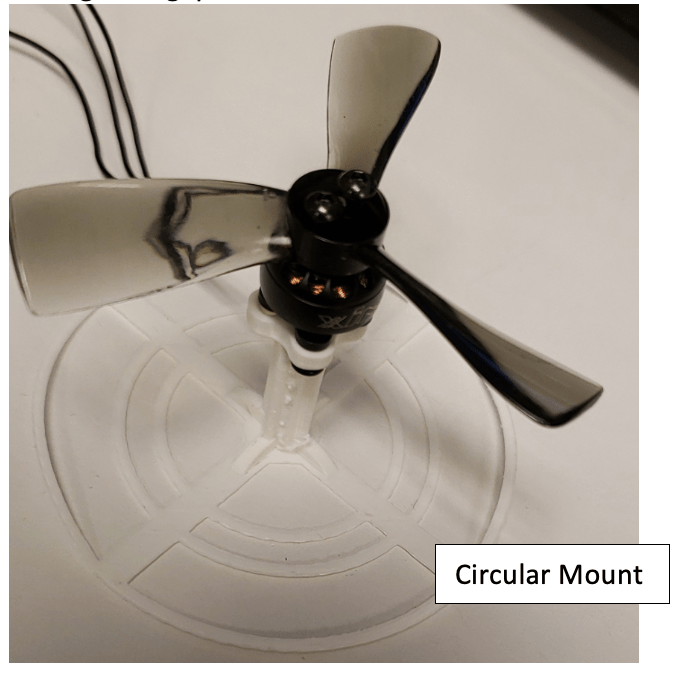

- For the tuna flapping (ellipse) you will need one motors. It will be connected to a circular mount. Pictured below is an example, motor and propeller. You may have different propeller shapes/colors in your kit.

- If your motors do not come with JST connectors pre-attached, you will need to attach female JST connectors to each of the motors. To do so, follow the same process as you have done previously by stripping the ends of the wires, twisting them, coating in solder, and wrapping with electrical tape.

- Screw in the Propellers – push the propeller onto the motor, line up propeller and motor holes, and then use hex screws to attach it.

- Screw the motor into the mount (you only need one circular mount) – you might need to clear plastic away from the screw holes on the mount before you begin. Use the hex screws included with the propellers. You will likely need to use the long end of the Allen wrench to reach the screws through the gaps in the mount.

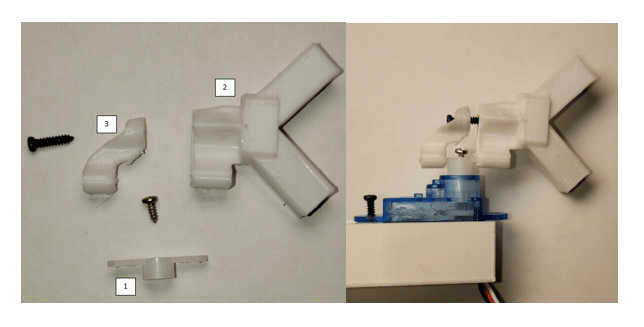

- Mount the servo that you prepared previously. Feed the wire through the holder, then slide the servo into the servo holder. Inside the servo bag, you will find Phillips head screws. Use one of the shorter silver screws and the short, straight actuator arm (the part labeled 1 in the picture below) to secure the servo. Try to leave the servo in the neutral position through this step. (A small screwdriver is included with the teacher kit).

- Attach the tail fin mount to the servo

- You will find this in the bag of 3D printed parts.

- Take the parts 1 and place it on top of the servor. part 3 to the back of part 2, so that the pieces meet.

- Screw the pieces together using a black screw from the servo bag. Attach the servo to the servo holder with a second black screw.

- Tape motor wires to servo mount leaving enough slack so that the motor can rotate.

- Insert balsa wood sticks into each hole of the Tail Fin Mount and attach construction paper via super glue or tape to the balsa wood sticks to create the flapping tail.

Test the Electronics

- Tape motor mounts to table to test electronics – you want the mount to be stable when the propeller turns on.

- Read over the software guide. You are now ready to upload code to the Feather and check for the MAC address of the controller. If there are others assembling the kit in the room they will all have the same MAC address so please refer to the Six Axis pair tool of the software guide.

- Attach circle mounted motor to the “up down” motor ESC, pin 15.

- Attach servo to the JST at pin 27.

- Attach battery to battery connector

- If you have not programed the feather, do not worry as it should be preprogrammed with the base code and should be able to connect the controller to the feather by turning on the controller and pressing start, this may take 10 – 30 seconds for the controller to pair to the feather.

- Using the right joystick of the controller up and down will move the motor on the circular mount, this will be used to move the blimp up and down.

- Using the left joystick of the controller right and left will move the servo left and right pointing the attached motor.

- Using the right and left trigger of the controller will move the motor that will be used to move the blimp forward, while also moving the left joystick simultaneously to steer the blimp.

Final Assembly

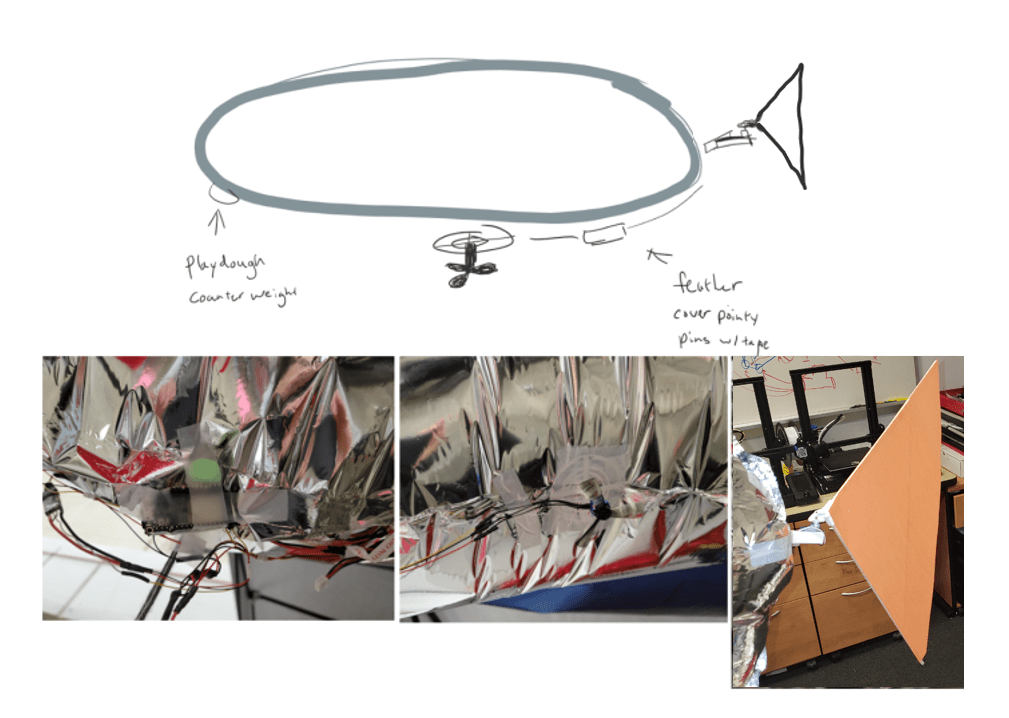

- Cover pointy pins on the board with electrical tape

- Follow the software instructions to prepare the controller and the board

- Fill the envelope with helium – make sure you secure the envelope with a string before adding helium so that it won’t float away (do not do this outside)

- Tape parts to envelope filled with helium

- Start by attaching the servo to the back of the blimpMake sure the wires are taped down so that they are not in the way of the propeller.Attach the other propeller to the bottom of the blimpAttach the feather and the battery between the two propellers.Make sure all wires are taped down and secured and out of the way of the propellersTape playdough to the front of the envelope – add more playdough until it is “neutrally buoyant,” i.e., floats without rising or falling

- Note: if you wish to move the motors and servos, you can make extension wires with 3 wires from the rainbow-wire stack and a male and female JST soldered to opposing sides.

- Bonus Exercise: see how the size and design of the tail affects the flight of the tuna

Last updated Nov 11, 2022.